Hot-pressed environmental protection equipment

In recent years, with the improvement of people’s quality of life, the tightening of national safety and environmental protection policies, and the sharp rise in labor costs, oil extraction practitioners have higher requirements for the supporting, automation, and oil safety and quality of oil extraction equipment. . In order to adapt to market changes, better serve users, and meet various needs of users, our company has specially launched a complete set of hot-pressing environmental protection equipment, and can design a personalized complete set of programs according to the specific conditions and special requirements of users.

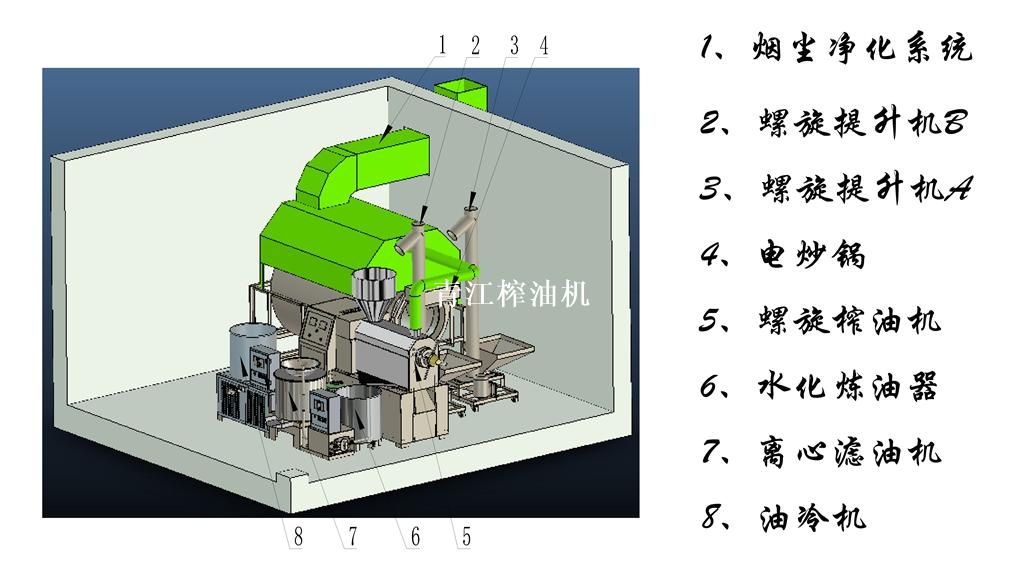

Process equipment layout drawing

Press process

Lifter A lifts the oil into the wok for roasting, and synchronously starts the soot purification system to collect and process the soot. After the oil is fried, it is put into the hoist B to be extracted into the oil press for squeezing, and the squeezed oil enters the hydration refiner for degumming , The degummed oil is pumped into the oil filter for oil residue separation treatment, and the separated oil is pumped into the oil cooler for cooling and bottling. The smoke and dust produced in the pressing process enter the smoke and dust purification system through the exhaust pipe for purification treatment, and the squeezed dry cake flows out of the chute to frame.

Main equipment and parameters

|

Equipment name |

Model specification |

Main parameters of equipment |

Remarks |

|||

|

Production |

Matching power (KW) |

Outer diameter size (mm) |

||||

|

Motor |

heating |

|||||

|

Electric wok |

HW80 |

150-200kg/h |

1.5 |

28 |

1750*900*1450 |

Supporting 95.10 series oil press |

|

HW90B |

250-300kg/h |

1.5 |

32 |

2000*1000*1500 |

Supporting 110 series oil press |

|

|

HW100 |

350-450kg/h |

2.2 |

38 |

2050*1120*1700 |

Supporting 130 series oil press |

|

|

Spiral elevator |

LTJ-140 |

1000kg/h |

1.1 |

|

600*600*1800 |

Increased by 1.8 meters, can be lengthened according to site conditions |

|

Screw oil press |

95.10.110.130 series |

150-400kg/h |

11-18.5 |

|

2400*700*1800 |

|

|

Hydration refiner |

SHJ-500 |

300 kg/h |

1.5 |

|

850*650*870 |

|

|

Centrifugal oil filter |

LXF500A |

100-200kg/h |

3 |

|

1273*760*900 |

Supporting 95.10.110.130 series oil press |

|

Oil cooler |

YL-500 |

100-300kg/h |

0.305 |

|

910*560*1021 |

Supporting 95.10.110.130 series oil press |

|

Fume purification system |

|

|

12 |

|

|

Non-standard production |

Remarks:

1. The whole set of equipment occupies about 20-30 square meters, the space height is about 3 meters, and the total electrical power is 60-80 kilowatts.

2, according to the specific conditions and special requirements of users, we can design a personalized package of programs.

Address: Ya'an Economic Development Zone, Sichuan Province

Email: qjgs@qingjiang.com.cn

Website: http://www.qingjiang.com.cn

Follow WeChat public account

Follow WeChat Mini Program

Copyright© 2020 Sichuan Qingjiang Machinery Co., Ltd. 蜀ICP备05031934号